Design

Caroba Plastics offers engineering assistance and support from the earliest stages of product design.

LEARN MORE

3d printing

Caroba Plastics offers full-service engineering consultation and support from the earliest stages of product design

LEARN MORE

The key to efficiency and part quality is a well maintained tool. Experience has proven a properly maintained and well designed mold will yield tremendous benefits to the customer

LEARN MORE

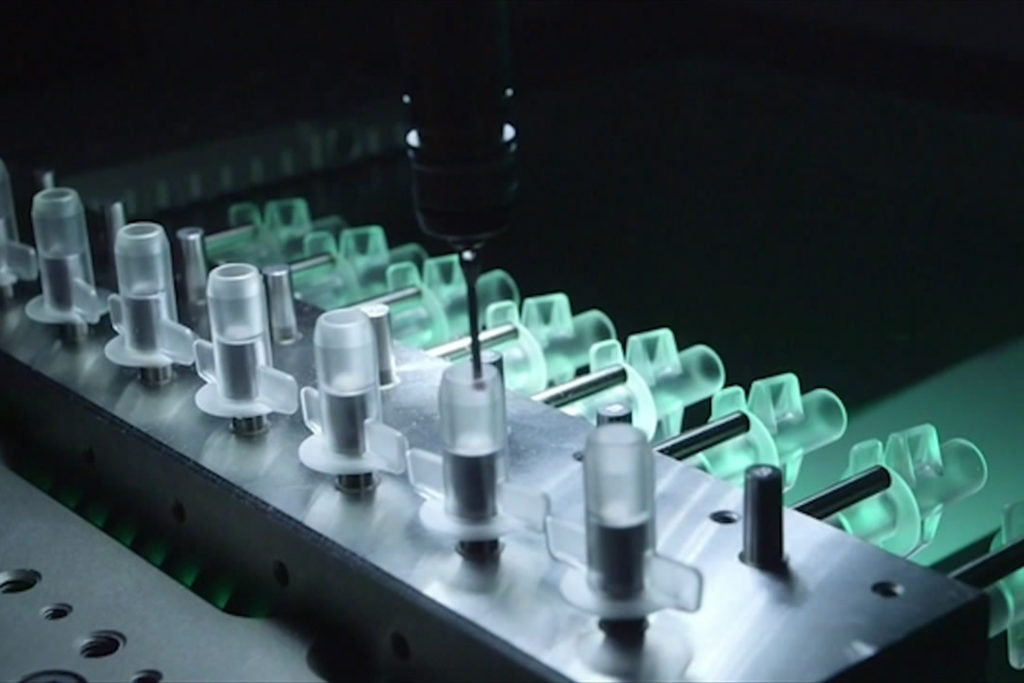

PRODUCTION

A successful injection molding company needs to be clean, well-organized, and staffed with experienced technicians and management to operate at peak efficiency.

LEARN MORE

CLEANROOMS

Caroba just recently expanded and added a class 10,000 hard wall clean room for medical and contract assembly.

LEARN MORE

secondary OPERATIONS

Our production coordinators are trained to ask the right questions to assure the customers’ expectations are known and documented in our work orders.

LEARN MORE

warehousing

Caroba Plastics had dedicated over 40,000 square feet for warehousing product for our customers. Our computer software maintains lot and location control of all products.

LEARN MORE