OUR QUALITY

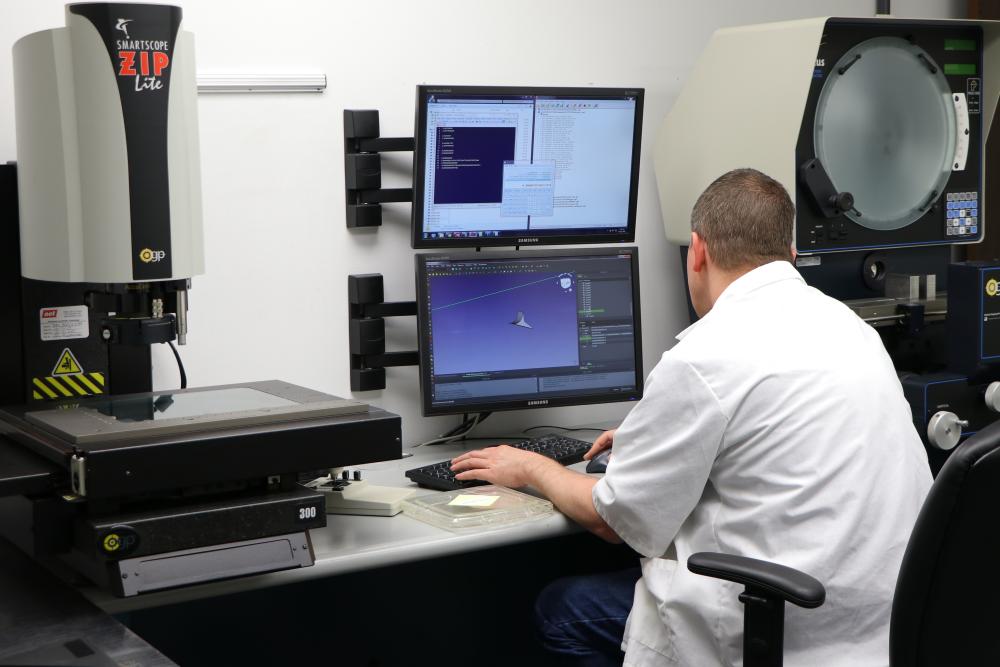

At Caroba, each item undergoes strict quality control at all stages of manufacturing by our In-Process Quality department and Metrology Lab. Our Quality teams are staffed with professional Quality Inspectors who measure and monitor our manufacturing operations to ensure consistent productivity and quality. These controls support Caroba’s ability to meet even the most stringent delivery schedules while maintaining ISO 9001 requirements as well as customer expectations.

Our proven results are assured by employing progressive quality systems with superb quality management principles. This is reflected in our certification.

Supported by professional engineering and documentation specialists, Caroba is very familiar with the ever-increasing regulatory requirements of the medical device and high technology industries. We have experience in product, packaging, and validation requirements of many leading medical OEM validation protocols (IQ, OQ & PQ), which can also include Process Validation, Measurement System Analysis (MSA), Design of Experiments (DOE), and Process Capability.

At Caroba, we recognize that our success depends on the success of our customers and the products that we manufacture for them. Our management staff can offer personalized services in everything from design assistance through delivery in an effort to reduce manufacturing costs to their lowest uncompromised level.

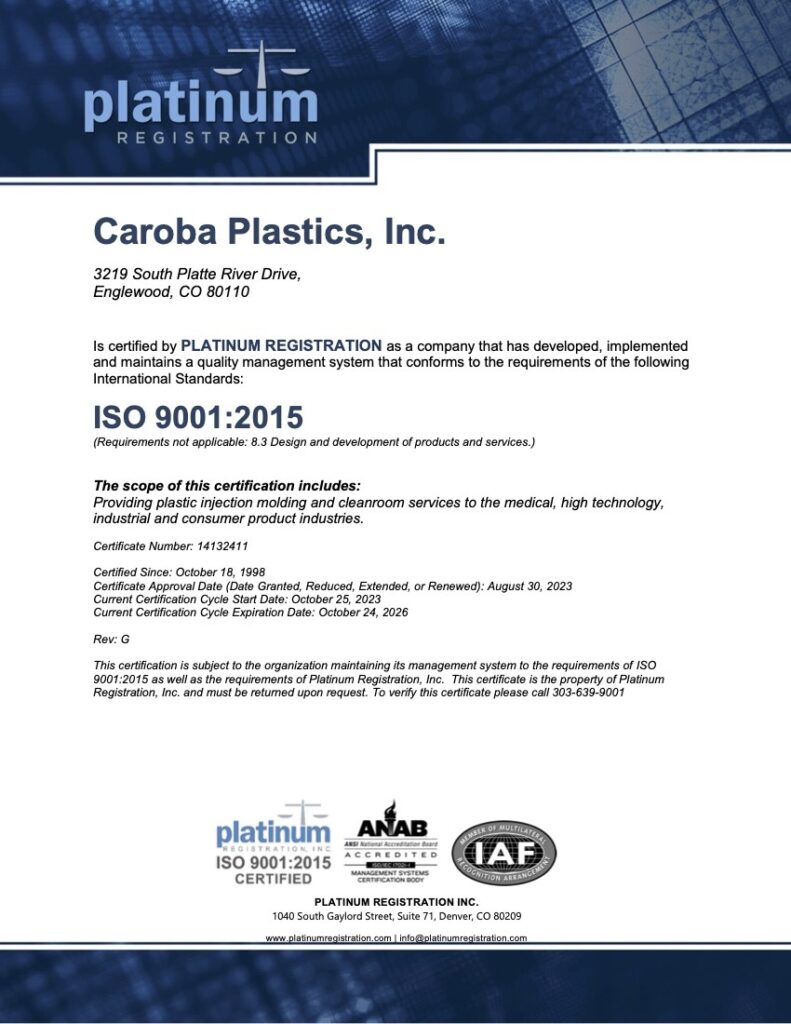

ISO CERTIFICATION

Caroba Plastics, Inc. is currently certified to ISO 9001:2015. We have continually maintained our ISO registration since October, 1998.

QUALITY HIGHLIGHTS

-

Caroba Plastics, Inc. offers Class 8 Clean Room Molding and Assembly. We also have the ability to develop automated part removal and packaging systems.

- We have full-time internal quality control capabilities supported by a well-equipped metrology department.

- Certified “dock to stock” or “cert to stock” status is available for injection molded components and molded components requiring secondary operations.

TESTIMONIALS

GRATIFYING

“IT WAS GRATIFYING TO SEE A COMPANY SO FOCUSED ON THEIR QUALITY MANAGEMENT SYSTEMS.”

GREAT PERSONAL ATTENTION

“WE FEEL LIKE CAROBA’S ONLY CUSTOMER! GREAT PERSONAL ATTENTION.”

EFFECTIVE QUALITY SYSTEM

“CAROBA’S QUALITY SYSTEM IS EFFECTIVE, IMPLEMENTED AND MAINTAINED WELL. EVERYBODY AUDITED WAS FORTHCOMING AND WILLING TO SHOW WHAT WERE ASKED FOR. THE FACILITIES ARE CLEAN AND TIDY.”

VERY GOOD QUALITY SYSTEM

“CONGRATULATIONS ON HAVING A VERY GOOD QUALITY SYSTEM AND ADEQUATE DOCUMENTATION TO ASSIST ME IN THE AUDIT.”